wire standard AWG(American Wire Gauge) introduction

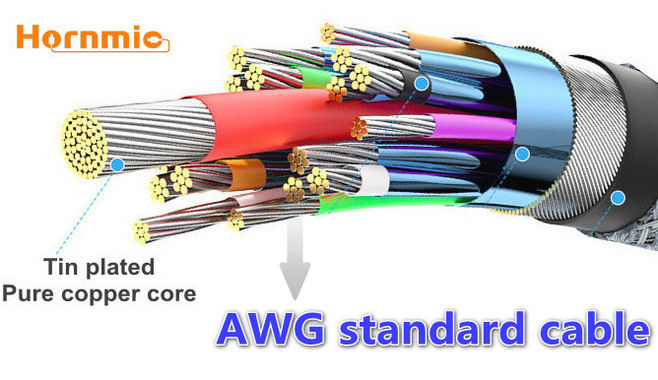

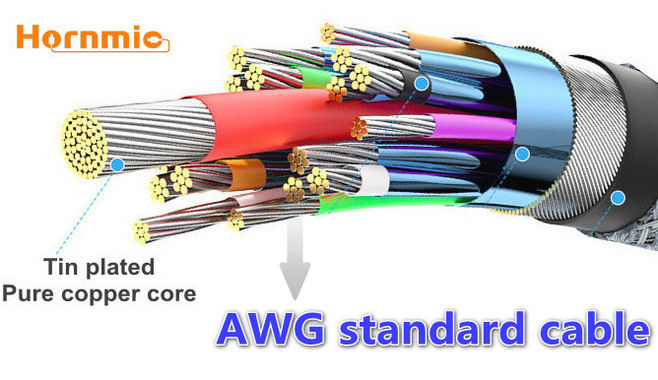

When we manufacture USB cable, the wire is processed according to AWG standard, which is the basis for cable to meet electrical performance, data transmission stability and service life. So what kind of standard is AWG? Let me introduce it to you in detail.

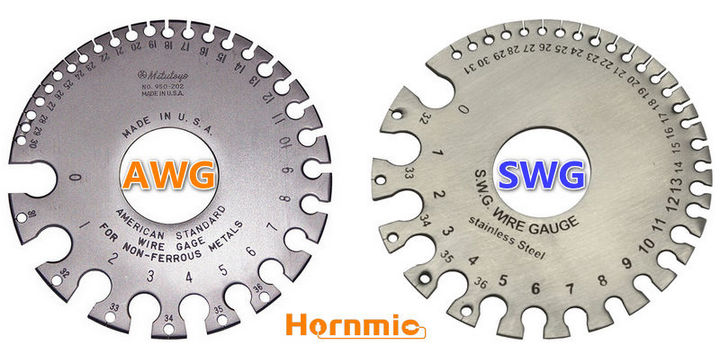

AWG : American Wire Gauge

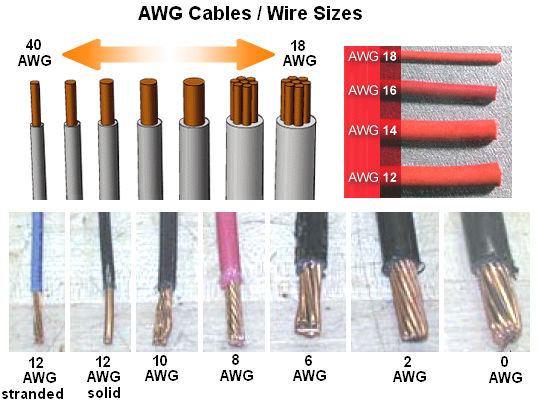

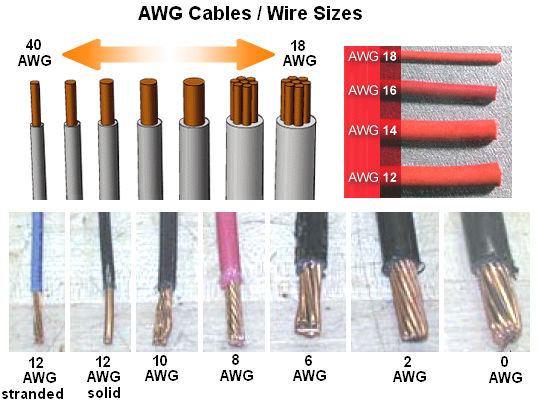

The full name of AWG is American Wire Gauge , this standardized wire gauge system has been used in the United States since 1857. It is a standard to distinguish wire diameters, also known as Brown & Sharpe wire gauge. The diameter of the conductor is closely related to the current carrying capacity of the conductor. The smaller the wire gauge number is, the thicker the wire diameter is, the greater the current it can carry; On the contrary, the larger the wire gauge number, the smaller the wire diameter, and the smaller the current it can carry.

Thick wires have better physical strength and lower resistance, but the thicker the wire, the more copper is needed to make the cable, which will make the cable heavier, more difficult to install and more expensive. The challenge of cable design is to use conductors with the smallest possible diameter (reducing cost and installation complexity) while ensuring the maximum capacity of the conductors at the necessary voltage and frequency.

Wire Gage History

300 years ago, the number of drawing was used as the symbol of wire thickness. The wire blank is No. 0, and one number is added every time it is pulled. Because there are many workshops with different processes, there are many wire number standards, but there are no unified regulations. This is of course very inconvenient in trade and exchanges. After 300 years of elimination, merger and change, some countries have changed to diameter measurement, but in Britain and the United States, the wire number representation is still in use today. American wire gauge (AWG), Birmingham wire gauge (BWG) and British Imperial standard wire gauge (SWG) are commonly used internationally.

AWG table is applicable to single, solid and round wires. The AWG value of twisted pair is determined by the total cross-sectional area of all wires, and because there is always some gap between twisted pairs, the diameter of twisted pair with the same AWG value is always slightly larger than that of a single wire.

The following is the AWG Cable Conductor size table. The data in the table include the impedance and allowable current (AMPS) of various conductors. The diameter values in the table apply to solid wires. The twisted pair shall be calculated according to the cross-sectional area of the copper wire. The following table is applicable to the case of DC, or the case of frequency less than or equal to 60 Hz, and skin effect is not considered.

** AWG size does not include the size of the insulation protecting a wire.

American Wire Gauge (AWG) Cable / Conductor Sizes and Properties

Cable Conductor Sizes and Properties.png)

AWG general rules of thumb - for every 6 gauge decrease, the wire diameter doubles and for every 3 gauge decrease, the cross sectional area doubles.

Resistance Notes: The resistance noted in the table above is for copper wire conductor. For a given current, you can use the noted resistance and apply Ohms Law to calculate the voltage drop across the conductor.

Current (ampacity) Notes: The current ratings shown in the table are for power transmission and have been determined using the rule of 1 amp per 700 circular mils, which is a very conservative rating. For reference, the National Electrical Code (NEC) notes the following ampacity for copper wire at 30 Celsius:

14 AWG - maximum of 20 Amps in free air, maximum of 15 Amps as part of a 3 conductor cable;

12 AWG - maximum of 25 Amps in free air, maximum of 20 Amps as part of a 3 conductor cable;

10 AWG - maximum of 40 Amps in free air, maximum of 30 Amps as part of a 3 conductor cable.

Skin Effect and Skin Depth Notes: Skin effect is the tendency of an alternating electric current (AC) to distribute itself within a conductor so that the current density near the surface of the conductor is greater than that at its core. That is, the electric current tends to flow at the "skin" of the conductor. The skin effect causes the effective resistance of the conductor to increase with the frequency of the current. The maximum frequency show is for 100% skin depth (ie. no skin effects).

What is American Wire Gauge for stranded wire?

AWG primarily describes single-strand solid wire. When multiple conductors, or stranded wire, use AWG, it gives the equivalent single-strand cross-section in AWG of all the strands cross-sections added together.

Stranded wire typically has three numbers to define it. These numbers include the AWG equivalent size, the number of strands and the AWG size of each strand.

As an example, 23 AWG 5/30 stranded wire has five strands of 30 AWG (0.0509 mm2) that equal one 23 AWG (0.258 mm2) wire.

What is the importance of American Wire Gauge?

The larger the cross-section of a wire, the less its resistance. Also, the larger the cross-section, the greater the amount of current (amperage) the wire can safely carry before overheating. A wire with a smaller gauge (larger diameter) can carry more power than one with a larger gauge. In general, a lower AWG number is better than higher AWG.

AWG is of primary importance for wires that will carry electrical power -- for example, home or business electrical wiring, extension cords or high-power wire in automotive or audio use. If too small a wire is used (high AWG), then the wire may overheat, melt or catch fire. Therefore, it is important that the current carrying capacity of a wire or circuit be considered.

Larger wire uses more metal needed, and therefore is more expensive.

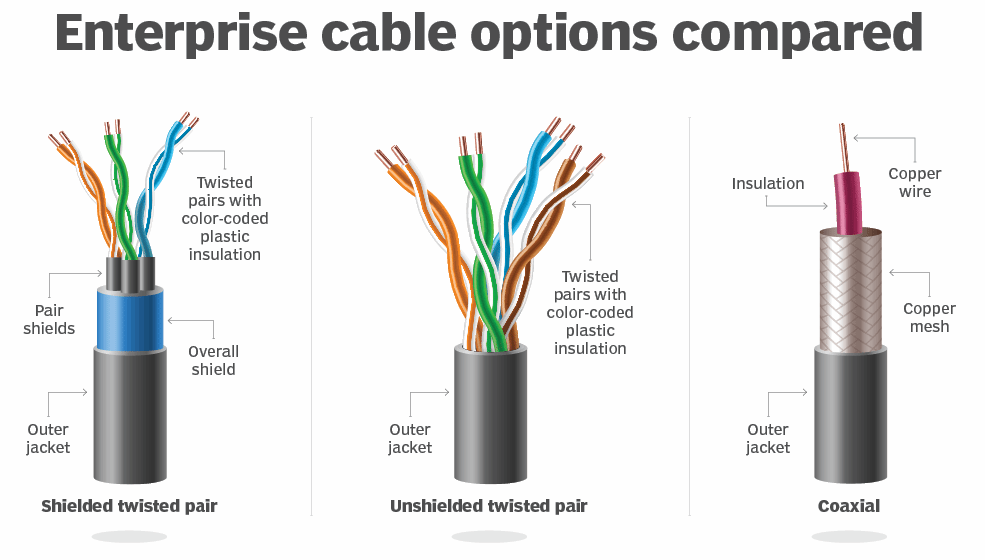

For signal carrying wires, such as audio hookup (RCA, S/PDIF) or video interconnect (VGA, DVI or HDMI), the AWG of the wire is not as important as for power wire. Since these electrical signals are usually low power, smaller AWG (larger wire) is not needed. In these situations, proper shielding and cable-pair twisting is more important for signal integrity than the AWG of the strands.

Lower AWG may increase the physical strength of the cable and can be useful in situations where it will be coiled, bent, pulled or otherwise handled to stop the cable from breaking internally. Stranded wire is also more resistant to breakage from bending than solid wire.

By HornmicLink_Bob Kuo @230915 09:55

Cable Conductor Sizes and Properties.png)