Whole process introduction of USB Cable production

Time:2023-09-14

Views:409

Whole process introduction of USB Cable production

Almost everyone uses USB cable to charge or transmit data to mobile phones every day. How is a seemingly simple USB cable produced?

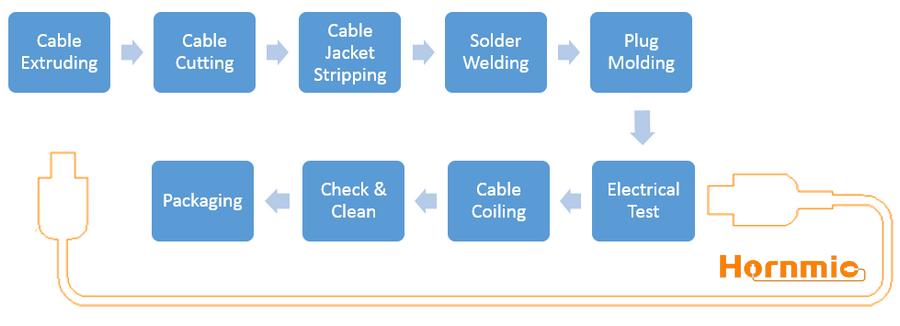

Process flow general view of USB cable manufacture:

1. Cable extruding , Extrude the cable according to the customer‘s specification, requirements, color and quantity.

2. Cable cutting , cut the rolled thread cable to the required length according to the product’s specification.

3. Peeling and stripping.

4. Solder Welding , Weld the USB plugs to both ends of the cable according to the function required.

5. Plastic molding , USB inner mold and outer mold according to the requirements.

6. Electrical Test , test the electrical performance of the USB cables.

7. Cable Coiling , Roll the USB cables into a coil according to the requirements of the drawing, and tie it tightly with a strap.

8. Check & Clean the USB cables.

9. Packaging.

The following is the detailed standard production process of USB cable:

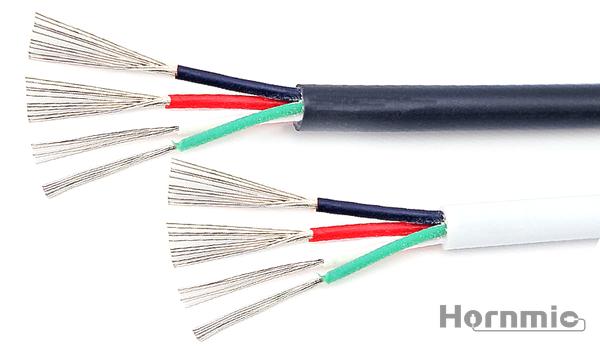

1. Cable Extruding with Copper wire & PVC

Extrude the cable according to the customer‘s specifications, models, requirements, quantity and color.

2. 裁线 Cable Cutting

According to the length of the product, cut the rolled cable coiling to the required length.

Extrude the cable according to the customer‘s specifications, models, requirements, quantity and color.

2. 裁线 Cable Cutting

According to the length of the product, cut the rolled cable coiling to the required length.

3. Cable Jacket Stripping

Strip the copper core wire of the specified length for subsequent welding.

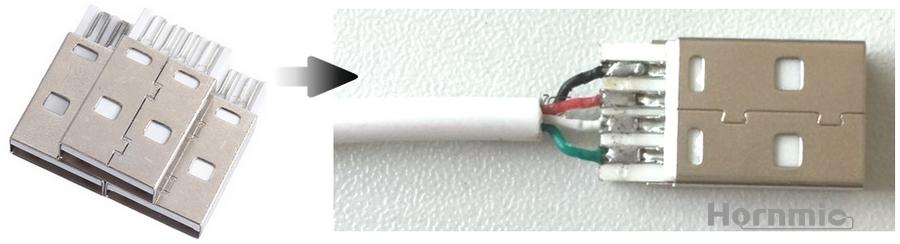

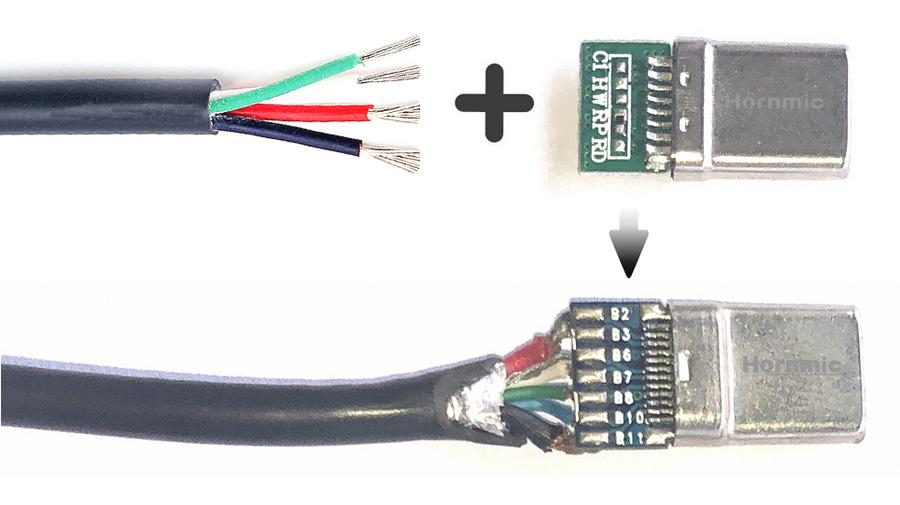

4、 Solder Welding

Weld the USB plugs to both ends of the cable according to the function required.

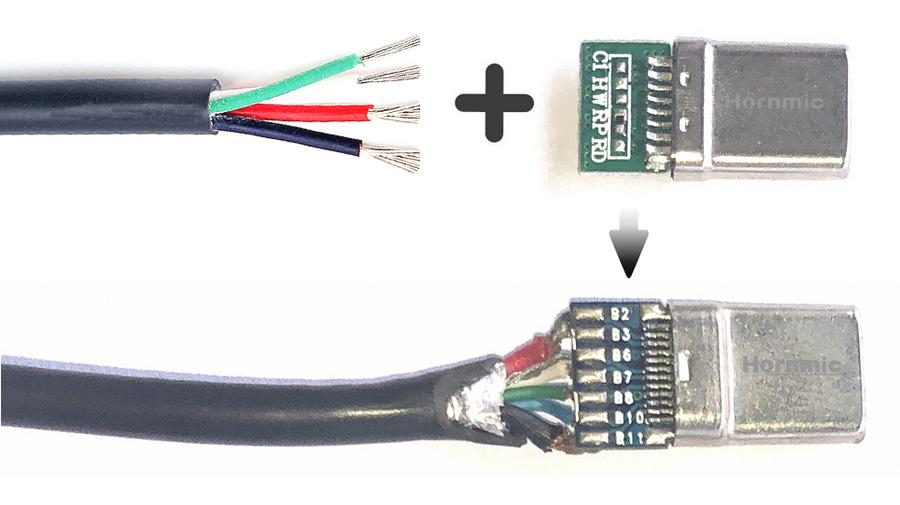

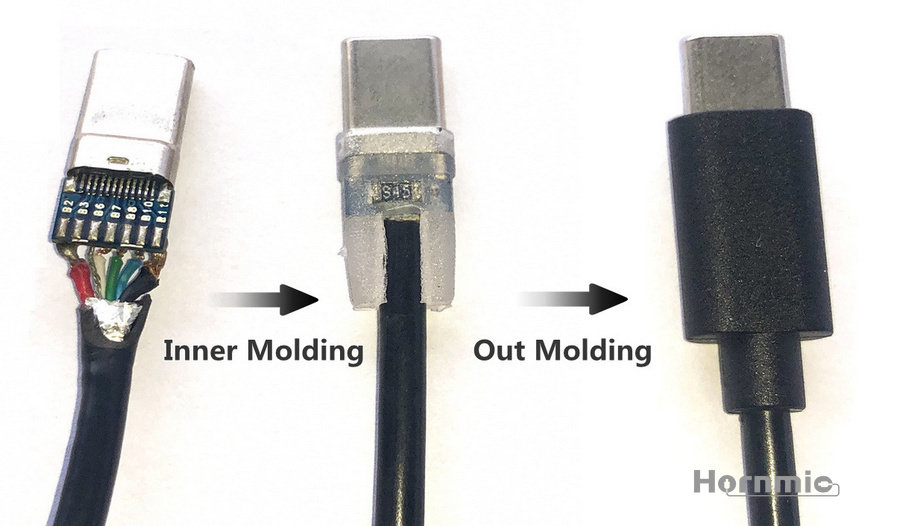

5、 Plastic molding of the 2 plugs

USB inner mold and outer mold according to the requirements for the both 2 plugs.

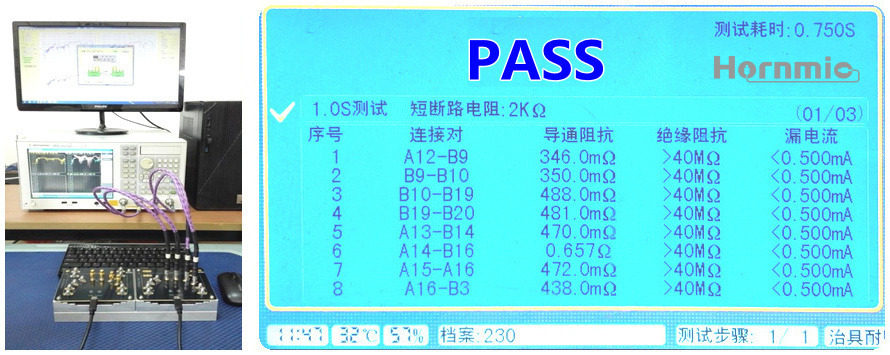

6、 Electrical Test

Electrical Test , test the electrical performance of the USB cables including below items:

Pins connection condition, whether there is short circuit or poor short circuit, conduction impedance, insulation impedance, leakage current, etc.

7、 Cable Coiling

Roll the USB cables into a coil according to the requirements of the drawing, and tie it tightly with a strap. The plugs should not be exposed to prevent scratching the cable.

8、 Check & Clean the USB cables

The plastic parts of the cable have uniform color, without discoloration, pits and scratches; The metal parts shall be free of scratches, dents and deformation.

Wipe the dust, impurity particles, oil stains, etc. on the surface of the cable.

9、 Packaging

Pack the specified quantity of USB cables according to the customer‘s requirements.

By HornmicLink_Bob Kuo @230914 20:10