USB线外被的材料类型

发布日期:2023-09-21

点击次数:527

The material types of USB cable jacket

Mobiles have basically become one of the electronic products we can‘t live without every day, and the cable, as the medium for charging and transmitting data to the phone, which we touch every day. This thin cable is made up of many components, including the jacket that we need to touch every day. Today, we will tell you about the materials commonly used for the outer jacket of the USB cable, let‘s learn more about it.

Common plastic materials types used for the outer jacket:

1. PVC

2. TPE

3. Braided Nylon

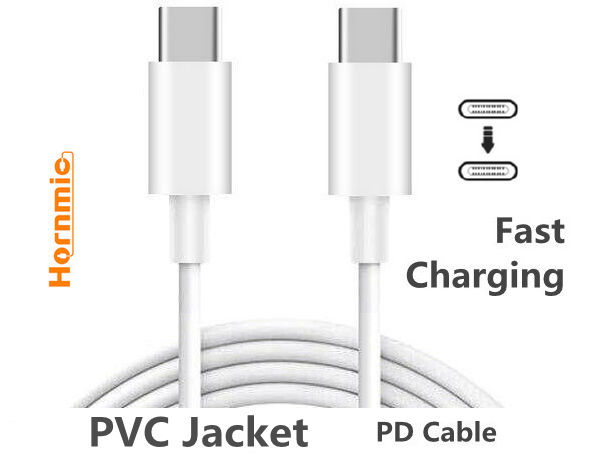

PVC jacket

PVC is a word that many people can often hear, in our life there are also many products are produced using PVC material, PVC material with non-flammable, high strength, climate change resistance and other excellent characteristics, in the past is also more mainstream cable outer jacket material.

Advantages of PVC jacket:

1. Material cost is low, the price is low, the current lower price of the USB cable on the market is usually this material.

2. Resistant to sweat, corrosion and friction.

3. Good insulation performance, excellent weather resistance, non-flammable and good safety, suitable for making USB cable jacket.

4. PVC cable is relatively inexpensive.

Shortcomings of PVC jacket

1. PVC material is hard, need to add softener, then becomes brittle and easy to break.

2. The softer the hardness of PVC, the more plasticizers are added. When too much plasticizer is used, some toxic particle molecules will be released under high temperature. So be careful not to let the cable in a high temperature environment, or not to let it heat up to high temperature.

3. Poor resilience of the material, feel stiff, after long time the bended cable can not be pulled straight.

4. The surface is usually not finely processed, and the surface is relatively rough and dull.

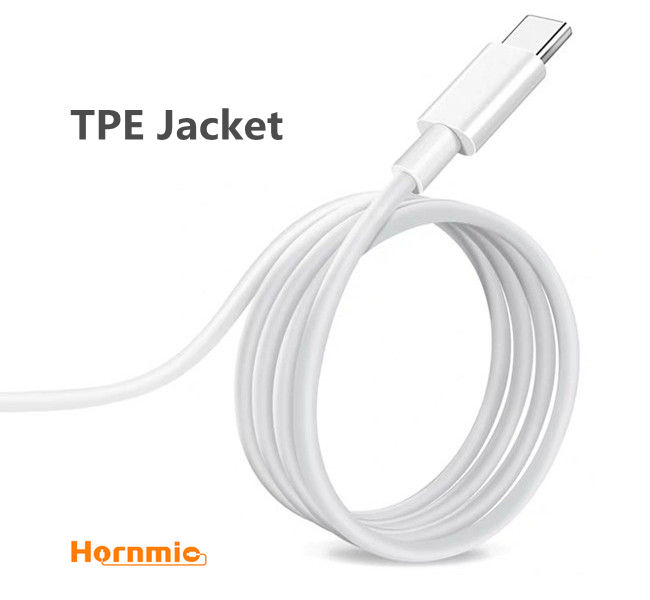

TPE jacket

TPE material is the main material to replace PVC material, TPE material is a general thermoplastic molding soft rubber material, TPE plastic has been improved a lot than PVC in the elasticity and toughness,, and it is more environmentally friendly, with the characteristics of recyclable.

Advantages of TPE jacket:

1 The USB cable jacket made of TPE has high flexibility, excellent tensile performance and is not easy to break.

2 TPE has good resilience, not easy to be tangled with comfortable and smooth feeling.

3 Excellent processing performance, easy to deploy a variety of beautiful colors, can achieve a frosted or delicate effect.

4 TPE is a green material, does not contain halogen and heavy metal elements, does not add toxic plasticizer in production process, which is much better than PVC. It’s safe and non-toxic without odor, will not cause any irritation to human skin.

5 Anti-aging performance, wear resistance, UV resistance are very good, long service life, coupled with the characteristics of not easy to break, usually a cable can be used for several years.

6 TPE has stable performance, is halogen-free flame retardant V0 level, phosphorus-free, ozone-resistant, safe and green.

7 It can be recycled to reduce the cost of raw materials.

Shortcomings of TPE jacket

1. Not resistant to dirt, the surface is easily stained with dust and oil.

2. When used in an improper manner, jackets are prone to bursting.

3. Material price is more expensive, so the USB cable with TPE jacket is slightly more expensive.

Braided Nylon jacket

Nylon braid is a polyamide fiber that can be made into long or short fibers. The nylon woven outer jacket is highly resistant to folding and durable, and protects the inside of the cable from being damaged.

Advantages of braided Nylon jacket:

1. Very good flame retardancy, abrasion resistance, electrical insulation.

2. High tensile strength, sturdy and durable.

3. The cable will not tangle.

4. With beautiful appearance, color and pattern can be changed on the surface of the cable.

5. Feel good, comfortable to touch.

Shortcomings of braided Nylon jacket

1. Greater hygroscopicity.

2. The cable’s dimensions are not stable enough.

Okay, this is all about the jacket’s material of USB cable. But there will be more and better materials for cable jacket in the future with the development of plastic material science and technology. Stay tuned to us and you will get more. Thanks for your reading and contact me freely.

By HornmicLink_Bob Kuo @230921 10:52