Why we must use standard copper wires for USB Cable?

Time:2023-09-11

Views:431

Why we must use standard copper wires for USB Cable?

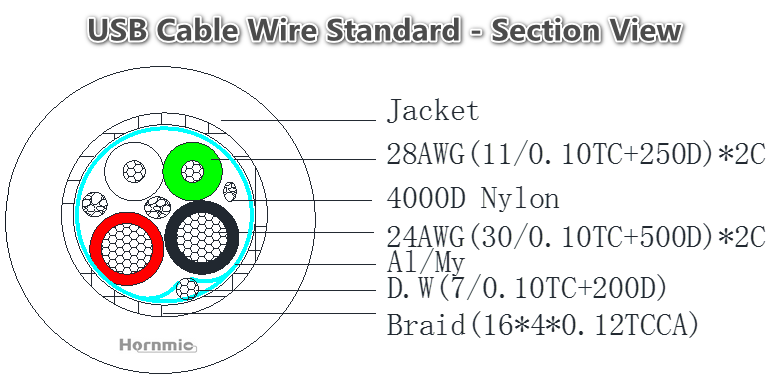

To ensure that the USB cable meets electrical performance, data transfer stability and longevity, the copper core of the USB cable must be processed in accordance with AWG standards. So why we must follow the AWG standards?

Disadvantages and pitfalls of non-standard cable:

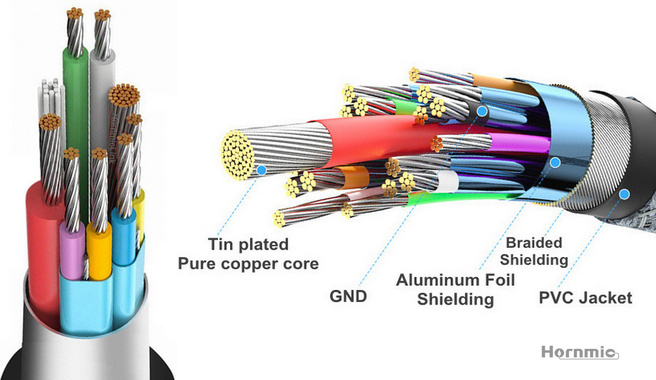

1. Non-standard wire cable core material is not qualified, copper core conductor accounts for 70%-80% of the cost of the wire. The copper conductor of the wire cable should use electrolytic copper. The purity of copper wire of poor quality copper is not enough, resulting in excessive resistance, the consequences are reduced data transmission speed, increased heat generation, so that users increased security risks.

Some companies, however, use recycled copper or copper-clad aluminum, copper-clad iron, copper-clad steel to pretend pure copper in order to reduce costs and obtain excessive profits. These copper conductivity is very poor, very easy to cause resistance exceeds the standard.

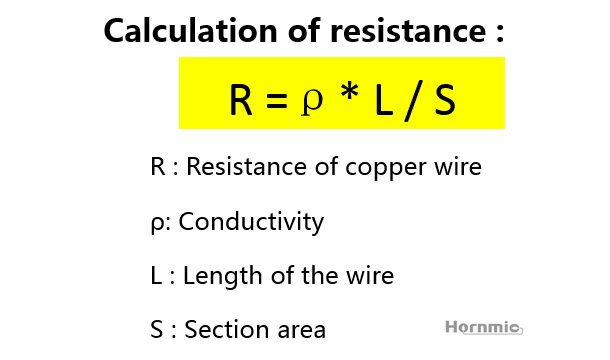

2. Non-standard wire cable cross-sectional area is not enough, the diameter of the copper wire will certainly not meet the requirements; Inferior quality wire using thinner copper wire to reduce the amount of copper used to reduce costs. In the same current, the diameter of the small copper wire carrying capacity is poor, easy to overheat, faster aging.

Calculation of resistance :

R =ρ* L / S__

R : Resistance of copper wire

ρ: Conductivity

L : Length of the wire

S : Section area of the wire

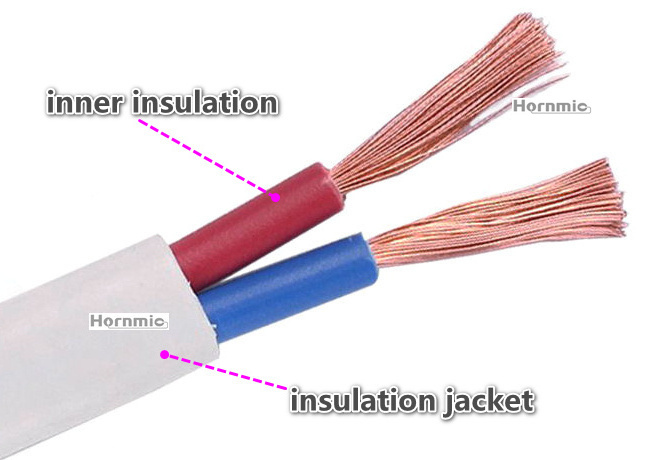

3. The insulation jacket of cable, mainly to prevent leakage, to ensure the safety of the role. If the insulation layer is not up to standard cable, aging resistance is reduced, and the insulator is easy to crack. Not only to shorten the life of the product, and make the live conductor exposed, threatening personal and property safety.

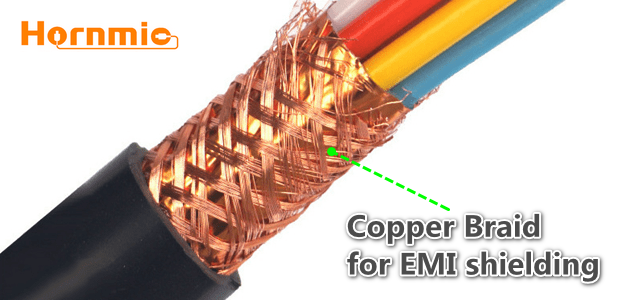

4. Low-quality cable without shielding or substandard braid, can not be effective EMI shielding, so that the signal transmission speed is reduced, so that the user experience is poor. And if a breakage occurs within the cable core, the current leaking out can flow along the shield layer such as the grounding network, when the shielded cable plays a role in the safety protection.

Standard Cable is relatively more expensive, but it is guaranteed to be genuine and safer for long-term use. Non-standard cable is cheaper, but its materials and performance are not up to standard, so the performance of the product decreases, the customer experience is poor, and the safety risk increases a lot.

By HornmicLink_Bob Kuo @230911 20:05