How to quickly judge the quality of cables

Time:2023-09-14

Views:368

How to quickly judge the quality of cables?

Harm of fake and inferior cables

Cables are related to the health of users, the safety of property and the use of devices. They are widely used. If fake and shoddy cables are used, it may cause short circuit, electric shock, and even fire. So poor USB cable is very bad for mobile device in charging and data transfer.

Characteristics of inferior cables

- Short length

- The resistance value does not meet the standard.The temperature of cables with excessive resistance may be too high under the same current, which will accelerate the aging of the external insulation layer, resulting in short circuit and fire.

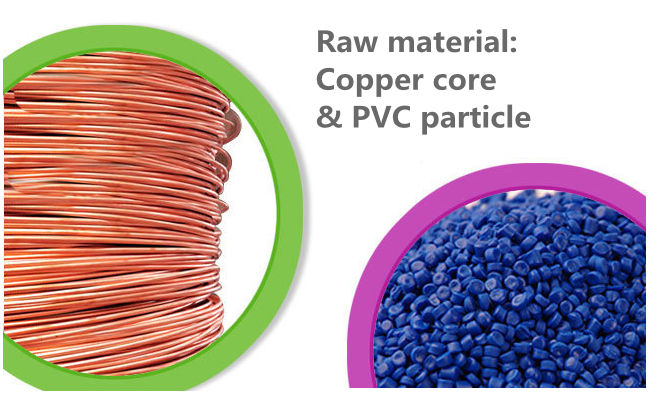

- Poor raw material

- The first bad way is to reduce the quality of copper. Using much cheaper impurity copper and recycled copper, the copper content is extremely unstable, resulting in a large increase in the resistivity of copper conductors. Copper conductors account for 80% of the cable cost. The other bad way is to reduce the actual cross-sectional area of the copper core. The direct consequence of these two methods is that the cable overheats during use, damaging the insulation plastic, causing a short circuit and causing a fire.

- Using low-quality insulating plastic, recycled insulating material is $300 cheaper per ton than qualified PVC plastic. However, the recycled insulating material has high impurity content, low mechanical strength, aging resistance and electrical insulation performance decline, which will directly lead to cable leakage.

Identification of inferior cables

1) Check the surface.

The plastic sheath of regular cables is soft and smooth, with uniform color. On its surface, several items on the product certificate should also be printed, such as: 3C certification mark, certification number, model, rated voltage, executive standard, factory name, etc. At the same time, the handwriting must be clear and not easy to erase.

2) Bending test

A cable can be bent repeatedly by hand. Those with soft hand feel, good fatigue resistance, large elasticity of plastic or rubber hand feel and no cracks on the cable insulator are excellent products. The insulation layer of low-quality cables seems to be very thick. In fact, most of them are made of recycled plastic. As long as you squeeze it a little hard, the extruded part will turn white, and there will be wire breakage after bending it for 4 ~ 6 times;

3) Tear the insulation

High quality insulating materials have certain mechanical strength and flexibility, which are easy to tear. And a piece of inferior cable can be torn or pinched off by hand;

4) Burning test

According to the standard, the insulation layer of the cable has certain flame retardancy. Peel off a section of insulation and ignite it. It is inferior wire that can continue to ignite.

5) Check the thickness.

Cut off a section of insulation layer to see whether there are pores on the section and whether the thickness is consistent. Air holes indicate that the insulating material used is unqualified. Where the thickness is thin, it is easy to leak electricity, and pores will also affect the withstand voltage strength.

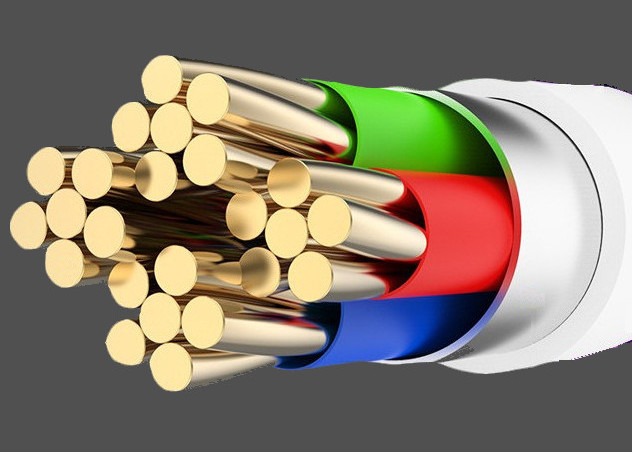

6) Check the copper wire.

By HornmicLink_Bob Kuo @230914 11:02